Wood

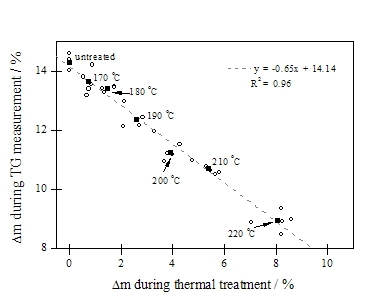

Thermal treatment is one of environmental friendly wood modification processes, developed in order to improve wood's natural durability and dimensional stability. Beside wood species, mainly isothermal temperature of heat-treatment and process duration affect these properties, which also correlate with the mass losses caused by the treatment. Since there is a lack of suitable external quality control methods, thermogravimetry as a potential method for determining the degree of thermal modification, is presented.

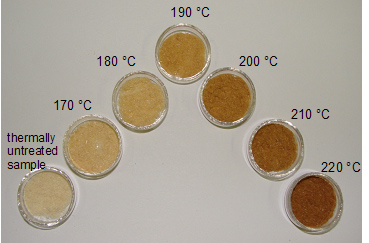

Milled spruce wood samples, thermally treated to a different degree. Isothermal treatment was performed under vacuum conditions for three hours.

Thermal decomposition, which was not completed during heat-treatment, had continued in wood samples during TG measurements. In temperature regions where calibration curves were constructed, depolymerisation and thermal decomposition of hemicellulose was predominant reason for the weight loss. Due to lower hemicelluloses content, lower weight loss during TG measurements in the range from 130 to 300 deg.C (nitrogen atmosphere) or from 130 to 250 deg.C (air atmosphere) exhibited samples, thermally treated at higher temperatures. Calibration curves, representing weight loss during TG measurements versus mass loss during previous heat-treatment, show good correlation.