High pressure DSC

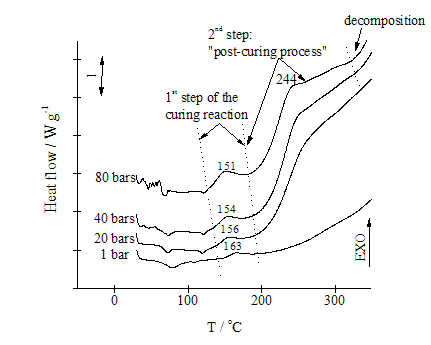

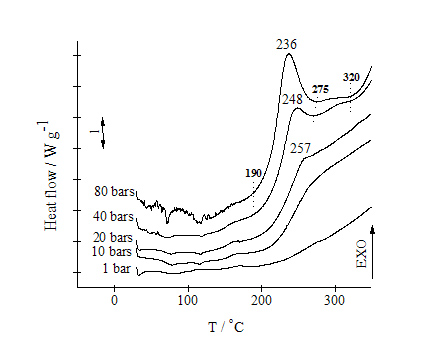

The influence of pressure on the polycondensation reaction between novolac resin (N) present in commercially available moulding compounds and hexamethylenetetramine (HMTA) was studied up to 80 bars under air and in an inert atmosphere. For a low HMTA content (N/HMTA = 98/2 weight ratio) high pressure enables the detection of two successive curing reactions. With increasing HMTA content the peak due to the first curing reaction becomes less pronounced at high pressure, while the enthalpy of the second increases. In an inert atmosphere both curing reactions are well observable even at ambient pressure and for lower HMTA content take place at lower temperatures, as expected. For the sample with N/HMTA = 98/2 the curing reaction was followed using TG-MS.

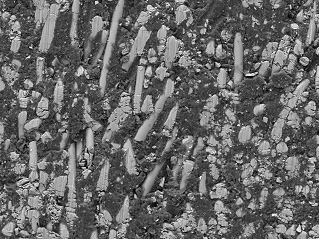

SEM micrograph of the cross section of a phenolformaldehyde (PF) moulding compound. Glass fibres (light colour) with an average diameter 12 µm are seen in various orientations in the matrix of cured novolac resin and fine- grain filler.

Influence of pressure on the shape of the DSC curve for a sample with N / HMTA = 98:2 under an air atmosphere.

DSC curves of a sample with N/HMTA = 80 : 20 under an air atmosphere.